Learn why septa quality matters and how to get the high-quality septa you need.

In analytical laboratories, every part of the mass spectrometry (MS) workflow plays a role in ensuring reliable results. Advanced instruments like gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-mass spectrometry (LC-MS) systems often take center stage, but small consumables such as silicone septa are critical to data quality.

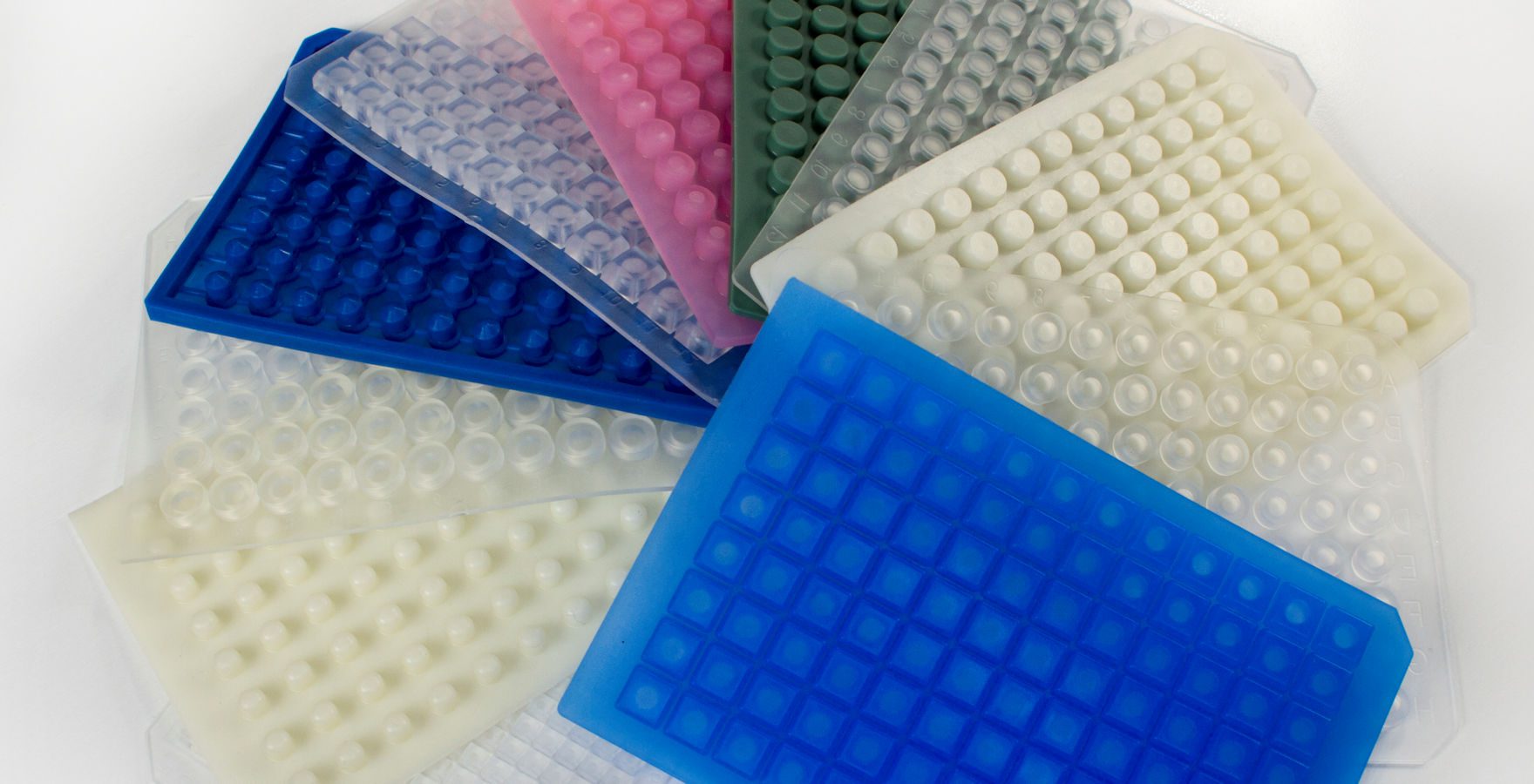

Frequently overlooked, septa serve as a key interface in sample introduction. Poor-quality or incompatible septa can cause contamination, inconsistent results, instrument downtime, and added expenses from repeated injections or reanalysis. Keep reading to learn more about septa quality, and contact SSP for standard and custom products.

How Septa Fit into Mass Spectrometry Workflows

Septa are typically used as part of a closure for sample vials or inlet systems, providing a seal that prevents sample loss while allowing needle penetration during injection. In GC-MS and LC-MS, septa form the first point of contact between the sample and the analytical system. Because they interact directly with samples and solvents, septa material quality, cleanliness, and chemical compatibility are essential for accurate and reproducible results.

How Low Septa Quality Can Affect Mass Spectrometry Analysis

There are four ways that low-quality septa can affect mass spectrometry analysis.

1. Contamination and Background Noise

Low-grade septa may release volatile or semi-volatile compounds that appear as ghost peaks or background signals in MS. This contamination can mask analytes of interest, reduce sensitivity, or complicate interpretation.

2. Leachables and Chemical Interference

Certain septa materials may leach additives and plasticizers into the sample. These compounds can interfere with ionization, leading to inaccurate quantification or false positives.

3. Mechanical Failures

Poor-quality septa may fragment or shed particles during repeated needle punctures (coring). These particles can clog injector liners, damage needles, and contaminate columns, leading to maintenance downtime and higher laboratory operating costs.

4. Reduced Reproducibility

Inconsistent septa performance (e.g., variable sealing, uneven resealing) can affect injection precision and retention time stability. This variability undermines method reproducibility and can compromise regulated testing.

How to Choose High-Quality Septa

To ensure reliable MS performance, choose septa that are:

- Low-bleed: Minimal contribution to background noise, verified for GC-MS use.

- Chemically inert: Resistant to solvents and sample matrices.

- Durable: Capable of withstanding multiple injections without coring.

- Thermally stable: With high tolerance to injection port temperatures.

How to Order Quality Septa

Silicone septa are relatively inexpensive consumables; however, the effects of septa quality on mass spectrometry results is profound. Investing in high-quality, MS-compatible septa, such as SSP’s Ultra Low Bleed Septa, minimizes contamination risk, enhances sensitivity, and extends instrument lifespan. In a field where accuracy and reproducibility are paramount, this small yet crucial consumable can have a significant impact.

For septa quality you can depend on, contact SSP.