Meet SSP at Pittcon 2025

Specialty Silicone Products (SSP) is excited to announce our participation in Pittcon 2025. This year’s Pittcon Conference and Exposition is scheduled for March 1-5, 2025, at the Boston Convention and Exhibition Center in Boston, Massachusetts (USA). SSP will be represented by Adam Stiles, President and Chief Operating Officer; Kevin Wickert, Sales and Marketing Manager; and Karen Heidenstrom, Senior Account Manager. SSP’s primary goal in attending Pittcon 2025 is to engage existing and prospective customers. We also look forward to discussing emerging industry trends and exploring new product opportunities. If you plan to attend Pittcon, we invite you to meet us there. To schedule a meeting, please contact Kevin Wickert at kwickert@sspinc.com. We look forward to the opportunity to collaborate and contribute to the advancement of laboratory science. What to Expect at Pittcon 2025 Pittcon was established in 1950 and is a dynamic international conference and exposition with a rich histroy. This annual event is a premier venue for presenting advances in analytical research and scientific instrumentation. It’s also a robust platform for scientific collaboration and continuing education. This year’s event features six tracks, 45 short courses, 375 speakers, 1200 presentations, and 500 exhibitors. Over the years, Pittcon has attracted a wide range of companies specializing in laboratory equipment, scientific instrumentation, and analytical services. From industry leaders to emerging innovators, Pittcon attendees gather to explore advances in laboratory science. They also discover cutting-edge technologies, network with other industry professionals, and gain exclusive access to educational sessions. SSP and SeptaSource at Pittcon 2025 For over 35 years, SSP has been a trusted name in the chromatography industry. Today, our SeptaSource products are world-renowned for using ultra-pure silicone septa and caps to ensure analytical purity. SSP’s silicone septa protect the purity of samples used in liquid chromatography (LC) and gas chromatography (GC), providing the reliability and performance that our customers depend on. SeptaSource products belong to these categories. Autosampler septa are designed for today’s laboratory equipment. GC septa are available in both disc-shaped and Shimadzu plugs. Ultra-low bleed septa are ideal for sensitive analytical techniques. EasyPierce™ septa supports multiple piercings with a needle or syringe. EPA/VOA septa promote the accuracy of volatile organic analysis (VOA). Custom septa are designed and made for application-specific requirements. Bonded Caps are made of polypropylene (PP) plastic and bonded to silicone septa. Magnetic Caps include screw caps and crimp caps for use with autosamplers. PFAS-free products use a PP film instead of a PTFE film in a 9-mm PP screw cap. Cap mats are for round or square plugs and fit precisely over the wells of microplates. Will you be at Pittcon 2025? SSP invites you to connect with us and to schedule a meeting by contacting Kevin Wickert at kwickert@sspinc.com.

SSP’s Ultra-Pure GC Septa: Made in USA with Analytical Purity

Discover SSP’s ultra-pure GC septa and the difference that analytical purity maks. Specialty Silicone Products (SSP) has been a trusted name in the chromatography consumables industry for over 35 years. We take pride in manufacturing all our products right here in the USA at our Ballston Spa, New York facility. With a commitment to quality and innovation, SSP provides gas chromatography (GC) septa with the highest level of analytical purity in the industry. Why Choose SSP’s Ultra-Pure GC Septa? Here are four reasons to choose GC septa from Specialty Silicone Products. Analytical Purity Our GC septa are formulated with ultra-pure silicone elastomers, ensuring precision and reliability. They are conditioned for: Ultra Low Bleed: Minimize baseline disruptions and prevent ghost peaks in chromatograms with our high purity septa. High Temperature Resistance: Withstand up to 240°C without degradation. Durability: Designed for multiple injections, resisting wear and coring over time. Syringe Injections In gas chromatography systems, samples are injected through a rubber septum into a heated vaporization chamber. SSP’s high-quality septa ensure: Leak-free sample introduction, including EasyPierce™ septa. Exceptional performance under high-temperature conditions. Custom Septa SSP also offers custom septa to meet your specific requirements, giving you the flexibility to tailor products for unique applications. Made in the USA and ISO Certified Every silicone septum is manufactured in the USA under our ISO 9001:2015-certified Quality Management System (QMS). This guarantees that SSP’s products meet the highest standards of quality, reliability, and performance. Learn More about Ultra-Pure GC Septa from SSP As a pioneer in chromatography consumables for over three decades, SSP stands behind every product we sell. We are committed to providing solutions you can rely on to support your laboratory’s success. From GC septa and Shimadzu plugs to customized solutions, SSP has the products you need for gas chromatography applications. Visit our website to learn more and choose SSP for unmatched quality, precision, and reliability in chromatography consumables. Video: SSP makes high analytical purity septa in bulk.

SSP: Your Partner for World-Class Autosampler Septa and Caps

Specialty Silicone Products (SSP) is proud to be a world-class manufacturer of autosampler caps and septa, serving the diverse and demanding needs of laboratories worldwide. From high-purity materials to state-of-the-art production capabilities, SSP delivers superior products that meet the rigorous requirements of today’s lab environments. Engineered for Compatibility and Performance SSP supplies autosampler septa and caps that are compatible with a wide variety of laboratory equipment, including both liquid chromatography (LC) and gas chromatography (GC) instruments. We use high-purity silicone rubber and premium-quality PTFE films to ensure exceptional performance. These materials are designed to handle the demanding conditions of laboratory applications, such as high temperatures, high pressures, and prolonged exposure to challenging environments. Our septa are: Tailored for Performance: Offering cleanliness, ease of piercing, and optimal compatibility with autosamplers. Versatile: Available for headspace vials and magnetic caps, as well as open-top or closed-top screw caps. Reliable: With superior re-sealing properties to maintain sample integrity. Unmatched Manufacturing Capabilities At SSP, our Ballston Spa, New York manufacturing facility is equipped with cutting-edge cutting and insertion equipment, ensuring precision and quality in every septa we produce. Unlike many competitors, we maintain large inventories of process materials, enabling us to fulfill orders quickly and efficiently. Our in-house machine shop allows us to design, build, and maintain all our molds and dies, reducing the time and cost required for new tooling. Whether you need standard products or custom solutions, SSP’s vertical integration means faster turnaround times and reduced costs for your laboratory needs. The Science Behind Superior Septa Autosampler closures play a critical role in automated sampling, where robotic devices pick, place, and pierce vials with a high degree of precision. SSP’s autosampler septa are designed to withstand these demanding conditions, offering exceptional durability, analytical purity, and ease of use. Key features include: Platinum-Cured Silicones: Our ultra-low bleed platinum-catalyzed silicones won’t release byproducts into samples, ensuring sample purity. Easy Pierce™ Technology: Balancing ease of needle penetration with re-sealability and resistance to evaporation. Unlike some septa that compromise on penetration, our Easy Pierce™ technology protects needles and prevents disruptions to autosampler motors. Application-Specific Designs: SSP septa are tailored to withstand high-pressure liquid chromatography and the extreme temperatures of gas chromatography ovens. Made in the USA for Quality You Can Trust Every SSP septa and cap is proudly made in the USA at our Ballston Spa facility, where quality control and customer satisfaction are our top priorities. Our autosampler septa come in a range of options, including: Specific PTFE films in various colors and thicknesses. Bags of 100 or 1000. Pre-assembled options for headspace vials or screw, snap, crimp, or magnetic caps. Why SSP? When you choose SSP, you’re not just buying a product—you’re investing in a trusted partner. Our commitment to quality, innovation, and customer service sets us apart as a global leader in septa and cap manufacturing. Whether you need standard products or customized solutions, SSP has the expertise and resources to meet your laboratory’s unique requirements. Contact us today to learn more about our autosampler septa and caps or to place your order. Experience the SSP difference and see why we’re the preferred choice for laboratories worldwide.

Why Silicone Septa Are the Superior Choice for Chromatography Applications

When it comes to chromatography, the materials you choose for your septa can have a profound impact on the quality and reliability of your results. Among the options available, PTFE/silicone septa consistently outperform alternatives like red rubber and butyl in purity, cost-effectiveness, and resealability. At Specialty Silicone Products (SSP), we pride ourselves on providing high-quality silicone septa that meet the demanding requirements of chromatography professionals. Keep reading to learn more and contact us to discuss your application. Purity Matters Purity is critical in both HPLC and GC applications. PTFE/silicone septa are engineered to minimize extractables, which can interfere with analytical results. Compared to red rubber and butyl, our septa offer significantly lower background and blank values. This ensures that your data is as clean and accurate as possible, even in highly sensitive tests. To further enhance purity, a thin layer of PTFE is laminated to the side of the septum facing the sample. This barrier limits the exposure of the silicone elastomer to solvents, reducing the risk of contamination while maintaining the chemical integrity of your samples. Versatility and Performance PTFE/silicone septa are incredibly versatile, thanks to their customizable formulations. SSP offers options tailored for specific applications, including variations in hardness (durometer) to accommodate different needle types. This adaptability ensures consistent performance across a wide range of chromatographic applications. With excellent chemical compatibility, low penetration force, and highly effective sealing and resealing properties, these septa are ideal for demanding environments. Whether you’re working with high-throughput or specialized chromatography, these septa provide the reliability and durability you need. Resealability and Cost-Effectiveness In applications requiring multiple punctures, resealability is a key consideration. Silicone’s natural elasticity makes it the perfect material for maintaining a tight seal even after repeated needle insertions. Unlike red rubber and butyl, which degrade more quickly, silicone septa provide long-lasting performance, reducing the need for frequent replacements. When factoring in the extended usability and minimized risk of contamination, PTFE/silicone septa offer excellent value for their cost. This combination of affordability and performance makes them a superior choice for labs seeking both quality and efficiency. Why Choose SSP’s Silicone Septa? At SSP, our septa are designed with the chromatography professional in mind. We understand the importance of precision, reliability, and cost in your applications. That’s why our silicone septa are rigorously tested to ensure consistent performance and meet the highest industry standards. Choose SSP for your chromatography needs and experience the difference that high-purity, versatile, and cost-effective silicone septa can make in your lab. Contact us today to learn more or request a sample!

Bonded Caps for Clean, Pure Septa

Specialty Silicone Products (SSP) makes bonded caps for clean, pure septa that won’t contaminate your laboratory samples. To ensure analytical purity, SSP uses a proprietary bonding technology to join our platinum-cured silicone septa to polypropylene plastic caps. These screw caps come in a choice of colors and sizes and are available with a single slit for venting during injection. Platinum-Cured Silicone Septa Silicones are formed into solid materials through a process called curing. There are two commonly used curing systems: peroxide and platinum. Peroxide curing is less expensive, but it releases byproducts called volatile organic acids (VOAs) that can leach or bleed into laboratory samples. Platinum curing is more expensive, but it does not release byproducts. SSP makes platinum-cured silicones and fabricates them into septa at our ISO 9001:2015, Made in USA manufacturing facility. Our products include high-purity ultra-low-bleed (ULB) septa for highly sensitive analytical testing. High-purity ULB septa are free from siloxanes, organic compounds that can affect test results from mass spectrometry or chromatography. Polypropylene Plastic Caps The polypropylene plastic that SSP uses in its bonded caps is a tough, lightweight material with excellent temperature and chemical resistance. These plastic screw-on caps also feature outer-diameter ribbing so that they’re easier to hold in the hand. Bonded caps come in standard colors that include white, blue, red, and black. They’re available in the following sizes. 9 mm screw 13-425 screw 24-400 screw 24-414 screw SSP supplies caps in bags of 100 or 1000. PTFE Liners and PFAS-Free Septa Caps Most of the bonded caps that SSP provides use a PTFE liner for added strength and toughness. Although our current silicone/PTFE septa are technically PFAS-free, PTFE is being lumped in with PFAS, a category of widely used “forever chemicals” that are the subject of state and federal regulations. Therefore, SSP is preparing for a range of regulatory scenarios. Thanks to the efforts of our in-house research and development team, SSP now offers a PFAS-free septa cap that uses a polypropylene film instead of a PTFE film. Our current offering is a 9 mm screw cap, but additional products are being developed and will be available soon. If you’d like to receive samples of bonded caps, contact us.

Elevate Your Laboratory Testing with SSP’s High-Quality EPA/VOA Septa

Specialty Silicone Products (SSP) is a trusted partner to laboratories around the world. We make high-quality septa and caps that are designed specifically for chromatography, including ultra-pure septa that meet water and soil testing requirements from the U.S. Environmental Protection Agency (EPA). These ultra-clean septa also support the accuracy of volatile organic analysis (VOA). Avoid Ghost Peaks SSP’s EPA/VOA septa are made from platinum-cured silicones and offer exceptionally-low siloxane bleed, helping you avoid the ghost peaks that can disrupt your gas or liquid chromatography analyses. We understand the critical importance of purity in your testing processes, which is why we are committed to providing products that ensure accurate and reliable results every time. Prevent Contamination In volatile organic analysis (VOA), avoiding contamination is paramount. Our EPA/VOA septa are engineered to prevent the introduction of contaminants such as siloxanes, fluorinated compounds, acetones, and solvents—ensuring the integrity of your samples during soil and water testing. By choosing SSP, you’re selecting a partner that provides the cleanest, most reliable products available. Choose the Option You Need SSP offers three main types of standard EPA/VOA products to suit your specific requirements: Stand-Alone Septa: Designed for those who require flexibility, our stand-alone septa are not fitted or bonded to caps, offering you versatility in use. Septa Fitted to Caps: Pre-assembled but not bonded, these septa are ready for immediate use and provide convenience without compromising quality. Bonded Caps and Septa: Using our proprietary process, we bond the cap to the septa, ensuring a clean, secure fit without affecting the septa’s low-bleed properties. Choose Specialty Silicone Products At SSP, we work tirelessly to create products that meet your needs and set the standard for quality and performance in the industry. Whether you’re conducting critical analyses or routine tests, our products are designed to support your work with the highest levels of purity and reliability. Thank you for your continued trust in SSP. We look forward to supporting your laboratory with septa and caps that help you achieve the most accurate and reliable results. For more information, contact us.

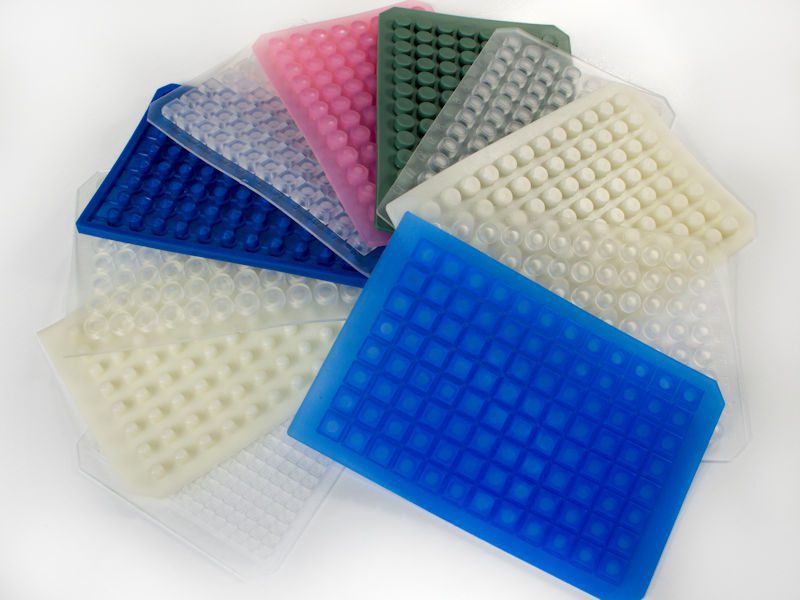

SSP’s Cap Mats: Precision and Protection for Chromatography Applications

When it comes to chromatography and other laboratory testing, the integrity of your samples is paramount. Specialty Silicone Products (SSP) understands this need and offers 96 well cap mats that provide superior protection and performance. These cap mats are engineered to fit precisely over the wells of microplates, ensuring each sample is securely sealed and protected. Cap Mats: Materials and Custom Options SSP’s cap mats are crafted from a proprietary platinum-catalyzed, premium-grade, FDA compliant silicone elastomer. This material is known for its durability and resistance to contamination. For applications requiring analytically pure conditions, our Ultra Low Bleed mats are specifically formulated to minimize siloxane peaks, ensuring that your results are free from interference. Cap Mats with Precision Fit and Versatility Our cap mats are available with either round or square plugs to suit different microplate designs. The 96 round cap mats come with two plug diameter options: 7 mm and 8 mm. The 7 mm plugs are ideal for plates holding samples over 1 ml, while the 8 mm plugs are suited for shallower plates with samples under 1 ml. This flexibility ensures a perfect fit and optimal performance for various laboratory needs. Round Cap Mats and Square Cat Mats: Easy Access and Sample Integrity To facilitate easy access to samples, SSP offers round cap maps and square cap mats with cross slits. These slits allow pipettes or syringes to penetrate the mat effortlessly, ensuring convenient sample retrieval without compromising the seal. This feature is crucial for maintaining the integrity of your samples by preventing evaporation and contamination. Cap Mat Customization to Meet Unique Needs At SSP, we understand that some projects require bespoke solutions. That’s why we offer custom cap mat configurations, including unique designs and colors. Our in-house, on-site machine shop allows us to design, build, and maintain custom molds efficiently, reducing lead times and costs. Whether you need a specific color to differentiate between samples or a unique design for a specialized application, SSP can accommodate your requirements. Made in the USA Cap Mats All our cap mats are manufactured at our facility in Ballston Spa, New York, ensuring stringent quality control and adherence to high manufacturing standards. We take pride in producing reliable, high-quality products that support critical analytical research and laboratory testing. Product Information for Cap Mats For detailed information about our standard cap mats, including dimensions and specifications, please refer to the product tables below. If you have unique requirements, do not hesitate to ask us about custom solutions. Ask SSP for Cap Mats With SSP’s 96 well cap mats, you can trust that your samples are protected, your results are accurate, and your research can proceed without interruption. Choose SSP for superior quality, reliability, and customized solutions in chromatography and laboratory testing. Contact us today.

SSP’s EasyPierce Septa for Chromatography Testing

At Specialty Silicone Products (SSP), we are dedicated to delivering the highest quality components for chromatography testing. Our innovative EasyPierce™ septa exemplify our commitment to manufacturing excellence, analytical purity, and reliability in demanding laboratory environments. Manufacturing Quality SSP’s EasyPierce™ septa are engineered with precision using strong, soft silicones that are platinum-cured for ultra-low bleed. This meticulous manufacturing process ensures that our septa maintain integrity and performance, even after multiple punctures. We also incorporate the highest-quality PTFE liners, designed to meet application-specific requirements, including color customization. Our stringent quality control measures guarantee that each septum meets the highest standards for performance and durability. Analytical Purity In chromatography testing, the purity of components is crucial to obtaining accurate results. SSP’s EasyPierce™ septa are designed to avoid fragmentation, thereby preventing contamination of samples. The cleaner materials we use provide superior barrier properties, essential for preserving the integrity of chemicals and compounds during long-term storage. By ensuring ultra-low bleed and utilizing premium materials, we help maintain the analytical purity necessary for precise testing in various applications, including water purity, vaccine, food and beverage testing, as well as drug and forensic analysis. Reliable Re-Sealing with EasyPierce™ Septa One of the standout features of SSP’s EasyPierce™ septa is their ability to support multiple piercings while remaining leak-free. Our advanced technology combines easy needle penetration with exceptional resealability and resistance to evaporation. Unlike other septa that may compromise on penetration ease, SSP’s EasyPierce™ septa strike the perfect balance, reducing the risk of needle breakage and preventing disruption to autosampler motors. This reliable re-sealing capability makes our septa ideal for laboratory diagnostics and chemical packaging, where repeated access to samples is often required. Regulatory Compliance SSP’s EasyPierce™ septa meet stringent regulatory requirements, including the guidelines defined by the United States Pharmacopeia (USP). Our septa are made from elastomeric materials that are FDA white-listed and USP Class VI approved, ensuring they are safe and effective for use in critical applications. This compliance underscores our commitment to providing products that meet the highest standards of safety and performance. Meeting Industry Needs with EasyPierce™ Septa SSP is at the forefront of supplying lined, resealable closures that cater to both end-user and bulk packaging needs. Our EasyPierce™ septa are available in standard and ultra-low bleed versions, offering versatility to meet diverse application requirements. Whether for chemical packaging or laboratory diagnostics, SSP provides custom solutions designed to enhance the efficiency and reliability of your operations. To learn more about our custom septa and how they can benefit your chromatography testing and chemical packaging needs, contact us today.

Custom Formulations and Product Analysis

Specialty Silicone Products (SSP) invites you to watch our Custom Formulations and Product Analysis video and see how we can help you turn your ideas for new materials into reality. At SSP, we have a dedicated R&D and Technology team that does the type of custom formulation and custom development work you’ll typically find only at larger companies. Yet we’re small enough to move quickly. Custom Formulations SSP can provide you with custom silicones in the shapes, sizes, thicknesses, pigments, and performance characteristics that you need. Whether you need a silicone with a certain set of properties or in a specific color, we can translate your application requirements into a new material you won’t find anywhere else. Plus, we’re willing to mix quantities that are too small for larger compounders to formulate. Product Analysis The custom sheets, rolls, and ready-to-mold compounds that SSP offers are available with a full certificate of analysis (COA) for each batch. At our in-house laboratory, we perform tests not only for material properties such as durometer, but also for flexural strength. Our flex tester isn’t the type of equipment you’ll find just anywhere but it lets us cycle materials to determine how long it will take before they crack. New Materials and Silicone Customization SSP’s custom formulation capabilities aren’t limited to brand new materials either. Our R&D and Technology Team can also determine how to produce custom sheets from existing materials in specialized shapes and thicknesses. SSP is your source for bespoke materials you won’t find anywhere else, and we also offer custom molded products such as EMI gaskets and EMI O-rings. Watch our new video to learn more and contact us to request a quote or for additional information.

SSP Prepares for Potential PFAS Restrictions

Per- and polyfluoroalkyl substances, more commonly called PFAS, are a category of widely used chemicals with components that break down very slowly over time. They are often called “forever chemicals” because once they are in the environment they tend to stay there. PFAS can be found in a wide range of consumer products like waterproof clothing, non-stick cookware, takeout food containers, and personal care products like shampoo and dental floss. There are thousands of different PFAS, and some have been found in the blood of people and animals, and in water, air, fish, and soil. Studies have shown that some types of PFAS in the environment may be linked to harmful health effects in people, but not all PFAS are the same. Nevertheless, some regulators are seeking to ban all PFAS broadly, and that’s causing companies to seek alternatives. Specialty Silicone Products (SSP) uses polytetrafluoroethylene (PTFE), a type of polymeric (long chain) PFAS, in the films on most septa products and as carrier films for cured roll products. SSP does not use any of the short-chain PFAS associated with health risks, and we ensure that short-chain PFAS are not present in the inputs we buy. Because SSP does use polymeric (long-chain) PFAS, we are preparing for regulatory scenarios ranging from an outright ban on all PFAS to a ban on only those PFAS with associated health risks. We recognize the effects that a full or partial ban would have on our customers and are tracking developments in both the United States and Europe. We’re also developing new septa products with new films and new materials and identifying suitable alternatives to use in our industrial products in case of a total PFAS ban. As part of our commitment to our customers, SSP is sharing PFAS information like you’ll find in this article. We’re also communicating with our suppliers to understand how they’re preparing for possible regulations, and talking to trade associations and other organizations that can help shape the new rules. In addition, we want you to know how the PFAS we use are different than some of the PFAS you may have heard about. Our products are not water-soluble, and they may ultimately be exempt from regulations What are PFAS? These substances have been released into the environment through the production, use, and disposal of PFAS-containing products such as paint, waterproof clothing, and firefighting foams. Two specific types of PFAS, perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA), have demonstrated health impacts. They are also among the PFAS substances that the U.S. Geological Survey detected in 45% of tap water samples across the United States. In 2021, the U.S. Environmental Protection Agency began requiring public water systems to test water supplies for 29 different types of PFAS, including PFOA and PFOS. In Hoosick Falls, New York, a 40-minute drive from SSP’s headquarters, Saint-Gobain and Honeywell were fined $45 million for PFAS remediation associated with PFOA contamination of the village’s water supplies. Like PFOS, PFOA is resistant to typical environmental degradation processes and is linked to cancer and other health concerns. What is the regulatory environment? Three U.S. states have passed legislation that may ultimately ban all PFAS in all products within the next ten years. Maine’s ban takes effect in 2030, and bans in Minnesota and Rhode Island take effect in 2032. Other states have enacted partial PFAS bans that affect specific classes of consumer products. Examples include food packaging, clothing, cookware, cosmetics, furniture, furniture, upholstery, and carpeting along with products for babies and children. In February 2023, the European Chemicals Agency announced a proposal to restrict the use of approximately 10,000 individual PFAS. The open consultation period ended in September 2023, and there isn’t a timeline for when European Union legislation could take effect. The results could range from a total ban on all PFAS to targeted bans on specific PFAS. Alternatively, there could be bans on specific products with exemptions for critical uses. What else do SSP’s customers need to know? The majority of SSP septa products consist of silicone bonded to PTFE. Given the possibility of a full PFAS ban or a partial ban that includes PTFE, we are developing alternative septa formulations using alternate protective polymer films and alternate elastomers that will provide our customers with the performance and purity they expect from SSP products without the use of PTFE. Currently, we have a PFAS-free septa that uses a polypropylene film/silicone rubber formula. We offer this septa in 9mm screw caps and snap caps. We hope to have other alternative options soon. Even without bans on PFAS, the mandated testing of water for specific PFAS means that fluoropolymer-free options for water sampling and analysis will be needed. SSP is working on a line of products that will be compatible with the EPA test methods (Method 531 and Methods 537 and 537.1) in addition to offering resealability, which the current options, like all-polypropylene caps, do not. Finally, we’d like to share that SSP is engaging with industry groups regarding fluorosilicones and potential efforts to ban or restrict them. We’re also continuing to monitor the legislative and regulatory environments so that we can provide customers with up-to-date information. To learn more about how we’re preparing for potential regulatory changes, contact SSP.