Silicone Septum FAQ

Specialty Silicone Products (SSP) provides answers to some frequently asked questions (FAQs) about silicone septum products. What is a silicone septum? A silicone septum is a precision‑molded sealing component used in chromatography vials, GC inlets, headspace vials, reagent bottles, and sterile sampling systems. It provides an airtight, resealable barrier that allows repeated needle punctures without compromising sample integrity. Why is silicone the preferred material for septa? Silicone is preferred because it combines elasticity, chemical resistance, and thermal stability. Silicone also exhibits low extractables, which helps maintain clean chromatographic baselines. Importantly, a silicone septum outperforms most elastomers due to its ability to reseal after puncture, resist coring, and maintain mechanical properties under heat and solvent exposure. What is the difference between a silicone septum and a rubber septum? A silicone septum offers superior thermal resistance, lower extractables, and better resealability than natural or synthetic rubber. Rubber septa are suitable for general laboratory use; however, silicone septa are preferred for chromatography, pharmaceutical sampling, and high‑purity applications due to their significantly lower extractables, which reduce the risk of leachables interfering with sample integrity and analytical results. What is a PTFE‑lined silicone septum? A PTFE‑lined silicone septum is a laminate consisting of a silicone base bonded to a thin PTFE film. The PTFE layer faces the sample and provides chemical inertness, while the silicone layer delivers resealability. This combination minimizes contamination, prevents sample absorption into the elastomer, and extends septum life during repeated injections. When should I choose a PTFE‑lined silicone septum instead of unlined silicone? Use a PTFE‑lined silicone septum when working with aggressive solvents, volatile organic compounds, or analytes that could interact with silicone. PTFE lining is also recommended for GC and HPLC autosampler vials, headspace vials, and any application where background contamination must be minimized. How does a silicone septum prevent contamination? A silicone septum maintains a vapor‑tight seal that prevents atmospheric exposure, evaporation, and particulate intrusion. Its resealing ability ensures that each needle puncture closes tightly around the needle track, reducing blow‑by leaks and protecting sample purity. What durometer (hardness) is best for a silicone septum? Most silicone septum products fall between 35–55 Shore A. Softer silicone improves resealability and reduces needle wear, while harder silicone resists coring and tearing. GC inlet septa often use slightly firmer silicone to withstand high temperatures and repeated injections. How often should a silicone septum be replaced? Replacement frequency depends on temperature, injection volume, and instrument type. In regulated chromatography workflows, septa are commonly designated as single-use consumables to control the risk of cross contamination and analytical carryover. GC inlet silicone septa may require replacement after 50–150 injections, while vial septa are used typically for a single analytical sequence. Septa should be replaced immediately if coring, leakage, discoloration, or any loss of sealing integrity is observed. What causes coring in a silicone septum? Coring occurs when small fragments of silicone are cut out by the needle tip. Common causes include: Dull or burred needles Excessively hard silicone septum materials High injection force Repeated punctures in the same location Incorrect needle bevel angle Coring can contaminate samples or clog GC liners, so early detection is important. Can a silicone septum withstand high temperatures? Yes. High‑purity silicone septum materials tolerate GC inlet temperatures up to 300 °C, depending on formulation. PTFE‑lined versions offer additional thermal stability and reduced outgassing. For autoclave sterilization, silicone maintains elasticity and sealing performance after repeated cycles. How should silicone septa be stored? Store silicone septa in clean, dry, dust‑free containers away from oils and UV exposure. Avoid touching the PTFE‑lined surface with bare hands to prevent contamination. For long‑term storage, keep septa in sealed bags to maintain cleanliness. What are the signs of a failing silicone septum? Technicians should watch for: Visible cracks or brittleness PTFE delamination Discoloration or swelling Increased injection pressure Ghost peaks or baseline drift in GC Any of these signs indicate that the silicone septum should be replaced immediately. Can silicone septa be sterilized? Yes. A silicone septum can be autoclaved, dry‑heat sterilized, or chemically sterilized depending on the application. PTFE‑lined versions tolerate sterilization well and maintain low extractables after repeated cycles. What thickness should I choose for a silicone septum? Common thicknesses range from 1–3 mm for vial septa and 3–5 mm for GC inlet septa. Thicker silicone septa provide better resealability and durability but require more needle force. Choose thickness based on instrument requirements and puncture frequency. Are silicone septa suitable for headspace analysis? Yes. A silicone septum is widely used in headspace vials because it maintains a gas‑tight seal under pressure and temperature cycling. PTFE‑lined versions prevent volatile analytes from interacting with the silicone layer. What makes a high‑purity silicone septum different? High‑purity silicone septa undergo controlled molding, post‑cure conditioning, and volatile removal to minimize extractables. These grades are essential for GC‑MS, pharmaceutical testing, and trace‑level environmental analysis. For silicone septa you can depend on, contact us.

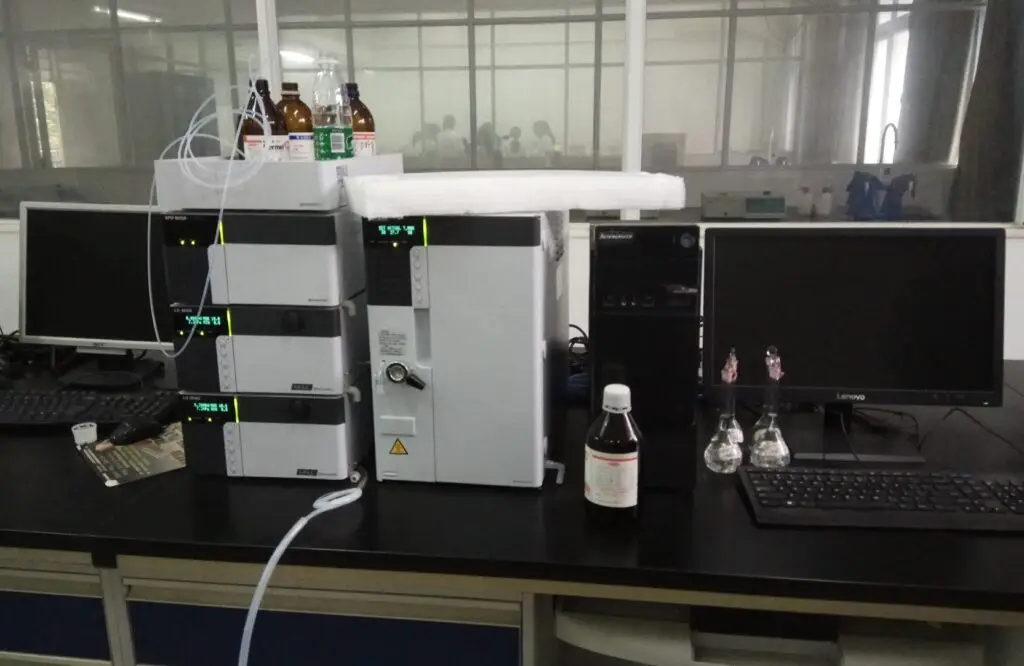

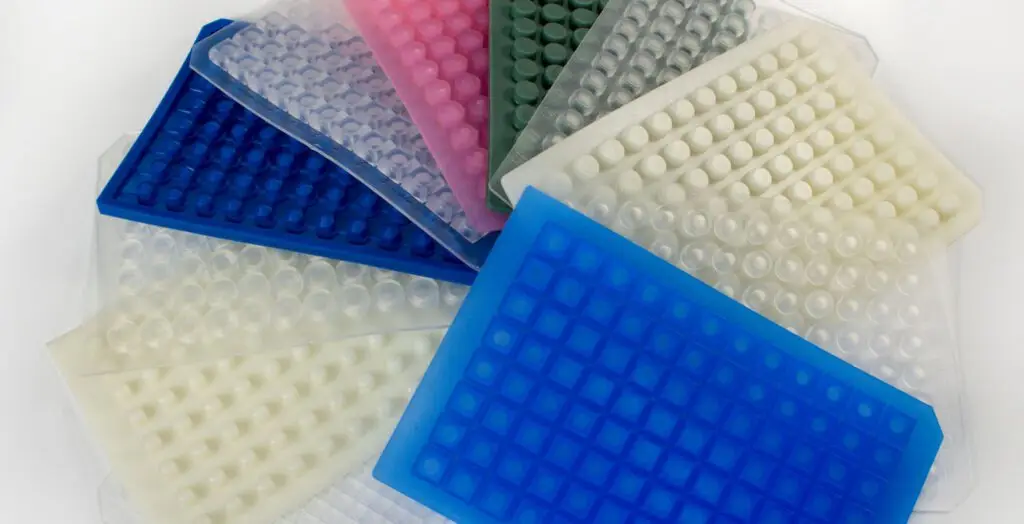

Meet SSP at Pittcon 2026

Specialty Silicone Products (SSP) will participate in Pittcon 2026, the premier event for laboratory science, from March 7-11, 2026, in San Antonio, Texas. SSP will be represented by Adam Stiles, President and Chief Operating Officer; Kevin Wickert, Sales and Marketing Manager; and Juan Carlos Reina, Business Development Manager for Laboratory Products. SSP’s primary goal in attending Pittcon is to engage existing and prospective customers. We also look forward to discussing emerging industry trends and exploring new product opportunities. If you plan to attend Pittcon 2026, we invite you to meet us there. To schedule a meeting, please contact Juan Carlos Reina at jreina@sspinc.com. What to Expect at Pittcon 2026 Pittcon is an annual conference and exhibition for presenting advances in analytical research and scientific instrumentation. It’s also a robust platform for scientific collaboration and continuing education. This year’s event features technical sessions, short courses, demonstrations, learning labs, and much more. SSP’s SeptaSource Products Specialty Silicone Products (SSP) has been a trusted name in the chromatography industry for over 35 years. To ensure analytical purity, our world-renowned SeptaSource products use ultra-pure silicone septa along with caps and cap mats. SSP also offers OEM and private label manufacturing capabilities and can supply customers with finished goods or septa sheets and rolls. Silicone Septa SSP’s silicone septa reliably protect the purity of samples used in liquid chromatography (LC) and gas chromatography (GC) applications. They sit inside a cap and provide a barrier that allows a syringe or needle to pierce through so that a sample can be withdrawn or injected. SSP’s silicone septa include: Autosampler septa for today’s laboratory equipment GC septa made from 100% pure premium silicone rubber, designed to deliver low bleed and long life. Ultra-low bleed septa for sensitive analytical techniques EasyPierce™ septa that support multiple piercings with a needle or syringe EPA/VOA septa that promote the accuracy of volatile organic analysis (VOA) Custom septa designed and made for application-specific requirements Caps and Caps Mats SSP’s SeptaSource products also include bonded caps, magnetic caps, and PFAS-free products. Bonded caps are made of polypropylene (PP) plastic and bonded to silicone septa Magnetic caps include screw caps and crimp caps for use with autosamplers PFAS-free products use a PP film instead of a PTFE film in a 9-mm PP screw cap. In addition, SSP makes silicone sealing mats (cap mats) that fit precisely over the round or square wells of microplates. This includes cap maps for 96-well plates, which are becoming increasingly popular in analytical and chromatography workflows because of their high-throughput capacity, compatibility with automation, and efficiency in sample preparation and storage. SSP’s Ultra Low Bleed platinum-cured silicone cap mats are formulated to minimize siloxane peaks, helping to ensure interference-free chromatography. Their consistency and purity make them the gold standard for laboratory and medical sealing applications. For 96- and 384-well plate sealing, platinum-cured silicone cap mats from SSP are the clear choice. See You at Pittcon 2026? Will you be at Pittcon 2026? SSP invites you to connect with us and to schedule a meeting by contacting Juan Carlos Reina at jreina@sspinc.com. We hope to see you there and look forward to the opportunity to collaborate and contribute to the advancement of laboratory science.

Why Does Septa Durometer Matter in HPLC?

Septa durometer, a measure of the septum material’s hardness, is usually measured on the Shore A scale. In High-Performance Liquid Chromatography (HPLC), it directly affects system performance and sample integrity. There are four reasons why. Need penetrations and resealing Leak prevention Chemical compatibility Autosampler reliability The following sections explain. 1. Needle Penetrations and Resealing A softer silicone septum (i.e., lower durometer septum) is easier for the autosampler needle to penetrate. This reduces stress on the needle and ensures less damage over time. However, a septum that is too soft may not seal properly and lead to leaks or evaporation. A septum that is too hard may require more force and risk needle wear or misalignment. There’s a greater likelihood of coring when the septum is too soft or the needle is thick. That’s because softer materials tend to tear instead of forming a clean puncture. A harder durometer septum reseals more reliably but can wear down the needle tip faster or cause mis-injections. 2. Leak Prevention Proper hardness ensures the septum reseals tightly after puncture. If the septum is too soft, there’s a risk of leaks, evaporation, and sample concentration changes. If the septum is too hard, there’s a risk of incomplete resealing or channeling around the needle puncture. 3. Chemical Compatibility Durometer influences how well the septum holds up against solvents used in HPLC (e.g., acetonitrile, methanol, water, buffers). Lower durometer septa may swell or degrade with aggressive solvents. There’s also a risk of bleeding or leachables. Medium hardness with lamination (PTFE layers) tends to preserve septa integrity against solvent attack. Harder, well‐laminated materials perform best in volatile or aggressive solvent environments. A balanced septa durometer reduces coring (i.e., tiny fragments of septum material breaking off into the vial, which can clog the column or detector). 4. Autosampler Reliability Modern HPLC systems use robotic autosamplers with precise needle movements. If the durometer is not optimal, the results may include misalignment, bent needles, or poor injection reproducibility. Septa Durometer and HPLC Instrument Manufacturer Recommendations HPLC instrument manufacturers recommend specific durometer septa because the performance of the autosampler and injection system depends on precise mechanical and chemical interactions. The durometer determines how the septum behaves when pierced by the autosampler needle and exposed to solvents, and the instrument design dictates which hardness will give the best results. In other words, Instrument manufacturers specify durometer in product specs because it: Helps labs match septa hardness to their autosampler needles (i.e., blunt vs sharp, small vs large bore). Guides selection for high-throughput lab. (If there are many punctures, then a medium/hard septa durometer is recommended.) Ensures compatibility with solvents and temperature conditions in your specific HPLC method. Septa Durometer Matters to HPLC Not all septa are created equal, and their durometer (hardness) must be carefully selected to achieve the right balance between needle penetration, resealing ability, chemical resistance, and long-term injection reliability in HPLC. This property directly influences how easily a needle passes through, how well the septum reseals, its resistance to coring, and its durability against solvents. Selecting an appropriate durometer helps ensure consistent chromatographic results, protects the instrument, and extends needle life. Because autosampler and injection system designs differ in needle geometry, force, and alignment, it’s also critical to follow the instrument manufacturer’s recommendations when selecting septa. This ensures optimal compatibility and maximizes performance in routine HPLC operation. For standard and custom septa, contact us.

The Advantages of 96-Well Plates and Sealing Cap Mats in Chromatography

96-well plates are becoming increasingly popular in chromatography and analytical workflows because of their high-throughput capability, compatibility with automation, and efficiency in sample preparation and storage. They enable the simultaneous processing of up to 96 samples, dramatically increasing throughput, reducing costs, and minimizing human error through automated handling. Their standardized well plate format also ensures compatibility with a wide range of robotic systems and analytical instruments, including liquid handlers and autosamplers commonly used in LC-MS applications. Main Advantages: High-throughput: A single plate can process 96 or even 384 samples at once, offering a major efficiency boost for high-throughput screening and analytical workflows. Automation compatibility: The standardized plate format integrates seamlessly with robotic systems for liquid handling, sample preparation, and loading—reducing manual error and increasing speed. Efficiency: Running many samples in parallel streamlines workflows, cuts down processing time, and lowers costs compared to handling individual vials. Sample preparation: 96-well formats are ideal for automated sample cleanup techniques such as solid-phase extraction (SPE) prior to LC-MS analysis. Sample storage: Plates provide a compact, organized, and standardized way to store large numbers of samples before or after analysis. The Key Importance of Proper Sealing To protect samples from contamination, evaporation, and cross-contamination between wells, an appropriate closure system is essential. Common sealing options include adhesive films (clear or aluminum) and silicone sealing mats (Cap Mats). Silicone sealing Cap Mats form a mechanical seal by capping each well simultaneously. They protect contents during assays, incubation, shaking, or long-term storage. These mats are available in various formats (flat or domed wells) and they remain stable across a wide temperature range: from autoclaving to cold storage temperatures. For workflows requiring access without removing the seal, pre-slit or pierceable silicone Cap Mats allow pipette tips or needles to penetrate while maintaining a tight reseal afterward. Choosing the Right Sealing Solution When selecting the best sealing method for your workflow, consider the following: Repeated or Long-Term Use: Adhesive films typically do not reseal after puncture, making them single-use. Silicone Cap Mats, however, reseal automatically, allowing multiple injections or sample withdrawals while preventing evaporation or concentration changes. Shaking, Mixing, or Centrifugation: Silicone Cap Matsmaintain a tight mechanical seal that won’t peel or loosen under agitation. Adhesive films can bubble, wrinkle, or detach during shaking or vortexing. High-Temperature or Sterilization Conditions: Platinum-cured silicone mats tolerate autoclaving (121 °C) and incubator conditions without degradation. Many adhesive films, however, can melt, warp, or leave residues when exposed to heat, making them unsuitable for sterilization or repeated heating cycles. Large-Scale Screening or Automation: Silicone mats are dimensionally consistent and compatible with robotic systems, allowing repeated piercing and resealing by automated liquid handlers. Adhesive films, on the other hand, are prone to tearing or sticking to robotic tips. Optical Measurements (PCR, Fluorescence): For optical assays that require light transmission, clear adhesive films are preferred since silicone Cap Mats can interfere with optical readings. Why Does Silicone Quality and Curing Method Matter on Well Plates Sealing Cap Mats? Not all silicone is created equal. The curing method used to convert silicone from a liquid polymer into a solid elastomer significantly affects purity, mechanical strength, and chemical resistance. What Does “Curing” Mean? “Curing” refers to the chemical crosslinking of silicone polymer chains using a catalyst, transforming the liquid polymer into a flexible, durable solid. The two main curing systems are platinum-cured (addition-cured) and peroxide-cured (free radical) silicone. Platinum-Cured Silicone Platinum-cured silicone uses a platinum catalyst to link hydride (-SiH) and vinyl (-CH=CH₂) groups on the polymer chains. Advantages include: Extremely pure and inert — no residual catalysts or byproducts. Odorless and non-leaching — ideal for biological or chemical assays. Excellent mechanical and thermal stability — withstands repeated autoclaving. Superior clarity and long-term color stability. Biocompatible and FDA/USP compliant — suitable for medical and food applications. Very low extractables and volatiles — critical for sensitive LC/MS or enzymatic work. Peroxide-Cured Silicone Peroxide curing uses organic peroxides that generate free radicals to crosslink silicone chains. This method produces volatile byproducts (e.g., acetic acid, alcohols, and water) that must be removed by post-curing. Disadvantages include: Potential contamination from residual byproducts. Odor and discoloration over time. Lower purity and thermal stability. While peroxide-cured silicone is cost-effective and acceptable for industrial uses (e.g., seals, gaskets, tubing), it’s less suitable for analytical or biological applications. Why is Platinum-Cured Silicone Preferred in Labs? For 96- and 384-well plate sealing Cap Mats, platinum-cured silicone is the clear choice because it: Avoids contamination of biological or chemical assays (critical for PCR, enzymatic, and pharmaceutical work). Withstands autoclaving, solvent exposure, and temperature cycling without degradation. Maintains consistent elasticity and compression for a reliable seal over multiple uses. In contrast, peroxide-cured silicone may release trace impurities that can: Interfere with enzyme reactions or cell cultures. Skew fluorescence or absorbance measurements. Contaminate analytical instruments such as LC/MS or GC systems. Platinum-cured silicones also offer better tensile strength, elongation, and durability across a wide temperature range. They resist degradation, exhibit minimal extractables, and release virtually no volatile organic compounds (VOCs), ensuring clean, reliable analytical results. SSP’s Ultra Low Bleed platinum-cured silicone mats are formulated to minimize siloxane peaks, helping ensure interference-free chromatography and LC/MS data. Their consistency and purity make them the gold standard for laboratory and medical sealing applications. Cap Mat Customization to Meet Unique Needs At SSP, we understand that some projects require bespoke solutions. That’s why we offer custom cap mat configurations, including unique designs and colors. Our in-house, on-site machine shop allows us to design, build, and maintain custom molds efficiently, reducing lead times and costs. Whether you need a specific color to differentiate between samples or a unique design for a specialized application, SSP can accommodate your requirements. All our cap mats are manufactured at our facility in Ballston Spa, New York, ensuring stringent quality control and adherence to high manufacturing standards. We take pride in producing reliable, high-quality products that support critical analytical research and laboratory testing. Custom 96-well Cap Mats Tailored to Your Needs At SSP, we recognize that some projects demand more than standard solutions. That’s why we

Understanding Septa for GC and HPLC

When performing Gas Chromatography (GC) or High-Performance Liquid Chromatography (HPLC), achieving reliable results depends on more than just the column and detector. A frequently overlooked but essential element is the septum, a small component that seals vials, protects samples from contamination, and supports accurate, consistent analysis. In this blog, we’ll explore what septa are, their role in GC and HPLC, and how to choose the right one for your application. What is a Septum? A septum is the polymer disk that sits inside the cap of an autosampler vial. It provides a resealable barrier that allows a syringe needle to pierce through, withdraw or inject a sample, and then reseal to maintain sample integrity. While small, septa must withstand chemical exposure, repeated injections, and system conditions such as heat or pressure. The type of septum you select can directly influence the accuracy and reproducibility of your chromatographic results. Septa for Gas Chromatography (GC) In GC, samples are vaporized and introduced into the system at high temperatures. GC septa must therefore tolerate elevated heat and frequent needle injections without degrading or bleeding (releasing volatile contaminants). Key Considerations Temperature resistance: GC inlets can reach 250–400°C, so septa must remain stable without melting or leaking. Low bleed: Septa should minimize volatile compounds that might interfere with sensitive detectors (e.g., MS). Durability: Frequent injections demand resistance to needle coring (fragmentation of septum material). Common Materials Silicone rubber: Flexible and resealable, ideal for multiple injections. PTFE-faced silicone: Combines chemical inertness with silicone elasticity; common in GC applications. Advanced formulations: Special low-bleed septa are engineered for GC–MS compatibility. Septa for High-Performance Liquid Chromatography (HPLC) Unlike GC, HPLC operates at ambient to moderately elevated temperatures and with liquid samples. HPLC septa must focus more on chemical compatibility and leachables than extreme heat resistance. Key Considerations Chemical resistance: Must withstand solvents such as acetonitrile, methanol, and buffers without swelling or degrading. Low extractables: Septa should not release compounds that could interfere with UV, MS, or fluorescence detection. Reseal-ability: Important for autosampler use, though demands are generally lower than in GC. Common Materials PTFE/silicone: Balances chemical inertness with dependable resealability, perfect for chemically demanding or multi-injection applications like autosampler runs, high-throughput testing, or long-term storage after piercing. PTFE-lined septa: Offer strong resistance to aggressive solvents. Polyethylene or butyl rubber blends: Typically utilized in applications where cost is a primary concern, and where samples are aqueous or exhibit low chemical reactivity, such as non-critical or single-injection procedures. How to Choose the Right Septum for GC or HPLC When selecting a septum for GC or HPLC, consider the following factors: Instrument type: GC vs. HPLC requires different resistance profiles. Sample chemistry: Ensure compatibility with solvents, buffers, and analytes. Temperature range: Match the septum’s heat tolerance to your injection port or sample storage conditions. Detection method: Low-bleed septa are essential for mass spectrometry. Injection frequency: Choose durable septa for high-throughput work. Best Practices for Septa Use Always use clean, fresh septa to prevent contamination. Avoid over-tightening vial caps, which can damage the seal. Store vials properly to reduce septa degradation. Replace septa regularly in GC inlets to maintain accuracy and reduce ghost peaks. Check that your syringe needle tip style is compatible with the septum. Follow the Instrument’s Manufacturer recommendations. Handle septa with clean, powder-free gloves to reduce the risk of introducing contaminants like skin oils, hand creams, etc. Keep unused septa in their original, clean packaging, and store them away from potential sources of contamination like chemicals or dust. Final Thoughts Septa may be small, but they are vital in ensuring reproducible, contamination-free results in both GC and HPLC workflows. Choosing the correct septum material and design for your application can reduce background noise, extend system life, and improve data quality. Whether you’re running high-temperature GC analyses or solvent-intensive HPLC separations, investing in the right septa is a simple but powerful step toward better chromatography. For more information, contact us.

Why Septa Quality Matters in Mass Spectrometry Analysis

Learn why septa quality matters and how to get the high-quality septa you need. In analytical laboratories, every part of the mass spectrometry (MS) workflow plays a role in ensuring reliable results. Advanced instruments like gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-mass spectrometry (LC-MS) systems often take center stage, but small consumables such as silicone septa are critical to data quality. Frequently overlooked, septa serve as a key interface in sample introduction. Poor-quality or incompatible septa can cause contamination, inconsistent results, instrument downtime, and added expenses from repeated injections or reanalysis. Keep reading to learn more about septa quality, and contact SSP for standard and custom products. How Septa Fit into Mass Spectrometry Workflows Septa are typically used as part of a closure for sample vials or inlet systems, providing a seal that prevents sample loss while allowing needle penetration during injection. In GC-MS and LC-MS, septa form the first point of contact between the sample and the analytical system. Because they interact directly with samples and solvents, septa material quality, cleanliness, and chemical compatibility are essential for accurate and reproducible results. How Low Septa Quality Can Affect Mass Spectrometry Analysis There are four ways that low-quality septa can affect mass spectrometry analysis. 1. Contamination and Background Noise Low-grade septa may release volatile or semi-volatile compounds that appear as ghost peaks or background signals in MS. This contamination can mask analytes of interest, reduce sensitivity, or complicate interpretation. 2. Leachables and Chemical Interference Certain septa materials may leach additives and plasticizers into the sample. These compounds can interfere with ionization, leading to inaccurate quantification or false positives. 3. Mechanical Failures Poor-quality septa may fragment or shed particles during repeated needle punctures (coring). These particles can clog injector liners, damage needles, and contaminate columns, leading to maintenance downtime and higher laboratory operating costs. 4. Reduced Reproducibility Inconsistent septa performance (e.g., variable sealing, uneven resealing) can affect injection precision and retention time stability. This variability undermines method reproducibility and can compromise regulated testing. How to Choose High-Quality Septa To ensure reliable MS performance, choose septa that are: Low-bleed: Minimal contribution to background noise, verified for GC-MS use. Chemically inert: Resistant to solvents and sample matrices. Durable: Capable of withstanding multiple injections without coring. Thermally stable: With high tolerance to injection port temperatures. How to Order Quality Septa Silicone septa are relatively inexpensive consumables; however, the effects of septa quality on mass spectrometry results is profound. Investing in high-quality, MS-compatible septa, such as SSP’s Ultra Low Bleed Septa, minimizes contamination risk, enhances sensitivity, and extends instrument lifespan. In a field where accuracy and reproducibility are paramount, this small yet crucial consumable can have a significant impact. For septa quality you can depend on, contact SSP.

SSP Welcomes Juan Carlos Reina

Specialty Silicone Products (SSP) is pleased to introduce Juan Carlos Reina as our new Business Development Associate for Laboratory Products. He succeeds Karen Heidenstrom, who is retiring after a distinguished career. Juan joins SSP after spending 26+ years working for Thermo Fisher Scientific’s Chromatography and Mass Spectrometry Division (CMD). He lives in Florida and will work remotely while reporting to Kevin Wickert, SSP’s Sales & Marketing Manager. Industry Experience Juan’s experience with chromatography consumables and commodity products is a great fit for SSP’s Laboratory Division, which produces septa, caps and cap mats under the SeptaSource name. At Thermo Fisher Scientific’s CMD Division, Juan was responsible for managing distribution partners in the Latin American region. Previously, he supported North American, European, and Asian partners in areas such sample handling and environmental and critical products. As a seasoned sales professional, Juan understands how to build strong, long-lasting relationships with partners, end users, and co-workers in various departments. Along with extensive business-to-business experience, he has a proven track record of delivering results. His skills include pricing and contract negotiations, market research, the development of key performance indicators (KPIs), annual operating plan (AOP) goal setting, project management, and strategic data analysis. Education and Interests Juan is bilingual in English and Spanish and proficient in Portuguese. He holds a degree in Business Administration from Pontificia Universidad Javeriana in Bogota, Colombia, and has worked as a Continuing Education Program Instructor for Spanish-speaking students at Cape Fear Community College in Wilmington, North Carolina. There, he also designed and taught Spanish language programs for English-speaking adults. When he’s not working, Juan enjoys volleyball, cooking, traveling, and photography. He also volunteers as a coach in a youth soccer league. Please join us in welcoming Juan Carlos Reina to the SSP Team and look for future communications from him regarding SeptaSource laboratory products.

Meet SSP at Pittcon 2025

Specialty Silicone Products (SSP) is excited to announce our participation in Pittcon 2025. This year’s Pittcon Conference and Exposition is scheduled for March 1-5, 2025, at the Boston Convention and Exhibition Center in Boston, Massachusetts (USA). SSP will be represented by Adam Stiles, President and Chief Operating Officer; Kevin Wickert, Sales and Marketing Manager; and Karen Heidenstrom, Senior Account Manager. SSP’s primary goal in attending Pittcon 2025 is to engage existing and prospective customers. We also look forward to discussing emerging industry trends and exploring new product opportunities. If you plan to attend Pittcon, we invite you to meet us there. To schedule a meeting, please contact Kevin Wickert at kwickert@sspinc.com. We look forward to the opportunity to collaborate and contribute to the advancement of laboratory science. What to Expect at Pittcon 2025 Pittcon was established in 1950 and is a dynamic international conference and exposition with a rich histroy. This annual event is a premier venue for presenting advances in analytical research and scientific instrumentation. It’s also a robust platform for scientific collaboration and continuing education. This year’s event features six tracks, 45 short courses, 375 speakers, 1200 presentations, and 500 exhibitors. Over the years, Pittcon has attracted a wide range of companies specializing in laboratory equipment, scientific instrumentation, and analytical services. From industry leaders to emerging innovators, Pittcon attendees gather to explore advances in laboratory science. They also discover cutting-edge technologies, network with other industry professionals, and gain exclusive access to educational sessions. SSP and SeptaSource at Pittcon 2025 For over 35 years, SSP has been a trusted name in the chromatography industry. Today, our SeptaSource products are world-renowned for using ultra-pure silicone septa and caps to ensure analytical purity. SSP’s silicone septa protect the purity of samples used in liquid chromatography (LC) and gas chromatography (GC), providing the reliability and performance that our customers depend on. SeptaSource products belong to these categories. Autosampler septa are designed for today’s laboratory equipment. GC septa are available in both disc-shaped and Shimadzu plugs. Ultra-low bleed septa are ideal for sensitive analytical techniques. EasyPierce™ septa supports multiple piercings with a needle or syringe. EPA/VOA septa promote the accuracy of volatile organic analysis (VOA). Custom septa are designed and made for application-specific requirements. Bonded Caps are made of polypropylene (PP) plastic and bonded to silicone septa. Magnetic Caps include screw caps and crimp caps for use with autosamplers. PFAS-free products use a PP film instead of a PTFE film in a 9-mm PP screw cap. Cap mats are for round or square plugs and fit precisely over the wells of microplates. Will you be at Pittcon 2025? SSP invites you to connect with us and to schedule a meeting by contacting Kevin Wickert at kwickert@sspinc.com.

SSP’s Ultra-Pure GC Septa: Made in USA with Analytical Purity

Discover SSP’s ultra-pure GC septa and the difference that analytical purity maks. Specialty Silicone Products (SSP) has been a trusted name in the chromatography consumables industry for over 35 years. We take pride in manufacturing all our products right here in the USA at our Ballston Spa, New York facility. With a commitment to quality and innovation, SSP provides gas chromatography (GC) septa with the highest level of analytical purity in the industry. Why Choose SSP’s Ultra-Pure GC Septa? Here are four reasons to choose GC septa from Specialty Silicone Products. Analytical Purity Our GC septa are formulated with ultra-pure silicone elastomers, ensuring precision and reliability. They are conditioned for: Ultra Low Bleed: Minimize baseline disruptions and prevent ghost peaks in chromatograms with our high purity septa. High Temperature Resistance: Withstand up to 240°C without degradation. Durability: Designed for multiple injections, resisting wear and coring over time. Syringe Injections In gas chromatography systems, samples are injected through a rubber septum into a heated vaporization chamber. SSP’s high-quality septa ensure: Leak-free sample introduction, including EasyPierce™ septa. Exceptional performance under high-temperature conditions. Custom Septa SSP also offers custom septa to meet your specific requirements, giving you the flexibility to tailor products for unique applications. Made in the USA and ISO Certified Every silicone septum is manufactured in the USA under our ISO 9001:2015-certified Quality Management System (QMS). This guarantees that SSP’s products meet the highest standards of quality, reliability, and performance. Learn More about Ultra-Pure GC Septa from SSP As a pioneer in chromatography consumables for over three decades, SSP stands behind every product we sell. We are committed to providing solutions you can rely on to support your laboratory’s success. From GC septa and Shimadzu plugs to customized solutions, SSP has the products you need for gas chromatography applications. Visit our website to learn more and choose SSP for unmatched quality, precision, and reliability in chromatography consumables. Video: SSP makes high analytical purity septa in bulk. https://www.youtube.com/watch?v=GsYd3V3OPyw&list=PLddGKKf6VXMlCD1g6NdTfIu0QJFKqZImu

SSP: Your Partner for World-Class Autosampler Septa and Caps

Specialty Silicone Products (SSP) is proud to be a world-class manufacturer of autosampler caps and septa, serving the diverse and demanding needs of laboratories worldwide. From high-purity materials to state-of-the-art production capabilities, SSP delivers superior products that meet the rigorous requirements of today’s lab environments. Engineered for Compatibility and Performance SSP supplies autosampler septa and caps that are compatible with a wide variety of laboratory equipment, including both liquid chromatography (LC) and gas chromatography (GC) instruments. We use high-purity silicone rubber and premium-quality PTFE films to ensure exceptional performance. These materials are designed to handle the demanding conditions of laboratory applications, such as high temperatures, high pressures, and prolonged exposure to challenging environments. Our septa are: Tailored for Performance: Offering cleanliness, ease of piercing, and optimal compatibility with autosamplers. Versatile: Available for headspace vials and magnetic caps, as well as open-top or closed-top screw caps. Reliable: With superior re-sealing properties to maintain sample integrity. Unmatched Manufacturing Capabilities At SSP, our Ballston Spa, New York manufacturing facility is equipped with cutting-edge cutting and insertion equipment, ensuring precision and quality in every septa we produce. Unlike many competitors, we maintain large inventories of process materials, enabling us to fulfill orders quickly and efficiently. Our in-house machine shop allows us to design, build, and maintain all our molds and dies, reducing the time and cost required for new tooling. Whether you need standard products or custom solutions, SSP’s vertical integration means faster turnaround times and reduced costs for your laboratory needs. The Science Behind Superior Septa Autosampler closures play a critical role in automated sampling, where robotic devices pick, place, and pierce vials with a high degree of precision. SSP’s autosampler septa are designed to withstand these demanding conditions, offering exceptional durability, analytical purity, and ease of use. Key features include: Platinum-Cured Silicones: Our ultra-low bleed platinum-catalyzed silicones won’t release byproducts into samples, ensuring sample purity. Easy Pierce™ Technology: Balancing ease of needle penetration with re-sealability and resistance to evaporation. Unlike some septa that compromise on penetration, our Easy Pierce™ technology protects needles and prevents disruptions to autosampler motors. Application-Specific Designs: SSP septa are tailored to withstand high-pressure liquid chromatography and the extreme temperatures of gas chromatography ovens. Made in the USA for Quality You Can Trust Every SSP septa and cap is proudly made in the USA at our Ballston Spa facility, where quality control and customer satisfaction are our top priorities. Our autosampler septa come in a range of options, including: Specific PTFE films in various colors and thicknesses. Bags of 100 or 1000. Pre-assembled options for headspace vials or screw, snap, crimp, or magnetic caps. Why SSP? When you choose SSP, you’re not just buying a product—you’re investing in a trusted partner. Our commitment to quality, innovation, and customer service sets us apart as a global leader in septa and cap manufacturing. Whether you need standard products or customized solutions, SSP has the expertise and resources to meet your laboratory’s unique requirements. Contact us today to learn more about our autosampler septa and caps or to place your order. Experience the SSP difference and see why we’re the preferred choice for laboratories worldwide.